Slide Bearings

|

-40

|

Structure

|

Features

|

|||||||||||||||||||||||||||||||||||

|

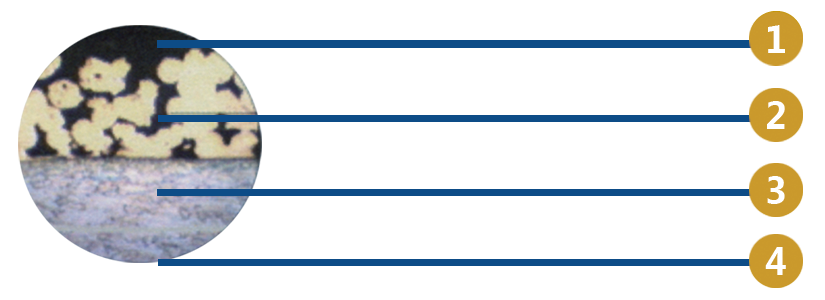

Steel bronze powder with PTFE/ fibre dry bearings

|

Suitable for dry running, low coefficient of friction, lower wear, good sliding characteristics, forming a transfer film can protect the mating metal surface, suitable for rotary and oscillating movement. High chemical resistance, low absorption of water and swelling.

The -40 has reduced friction and better wear resistance over the common -50 under lubricated operation. |

|||||||||||||||||||||||||||||||||||

|

Typical Application

|

|||||||||||||||||||||||||||||||||||||

|

Developed for heavy duty, oil lubricated, hydraulic applications... Automotive suspension struts, shock absorbers guide bushing, hydraulic cylinders, gear pumps, motors, axial piston pumps and in the oilfield for Downhole Drilling Motors. -40 is designed for use mainly under lubricated conditions and shows excellent wear resistance, low static and dynamic friction coefficient. |

|||||||||||||||||||||||||||||||||||||

|

Technical Data

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||